Dogwood Wagon

TIG Welding | Tube Bending | Woodworking

An ergonomic, beautiful wheelbarrow for the master home gardener. A striking tool to complement a verdant garden.

Materials.

| 1”x.0625” square steel tubing

| Marine grade plywood

| 16ga mild steel sheet

| Cherry

| 3/8” hardened steel axel

| Purchased wheels, bearings, & hardware

| Penetrol finish

Processes.

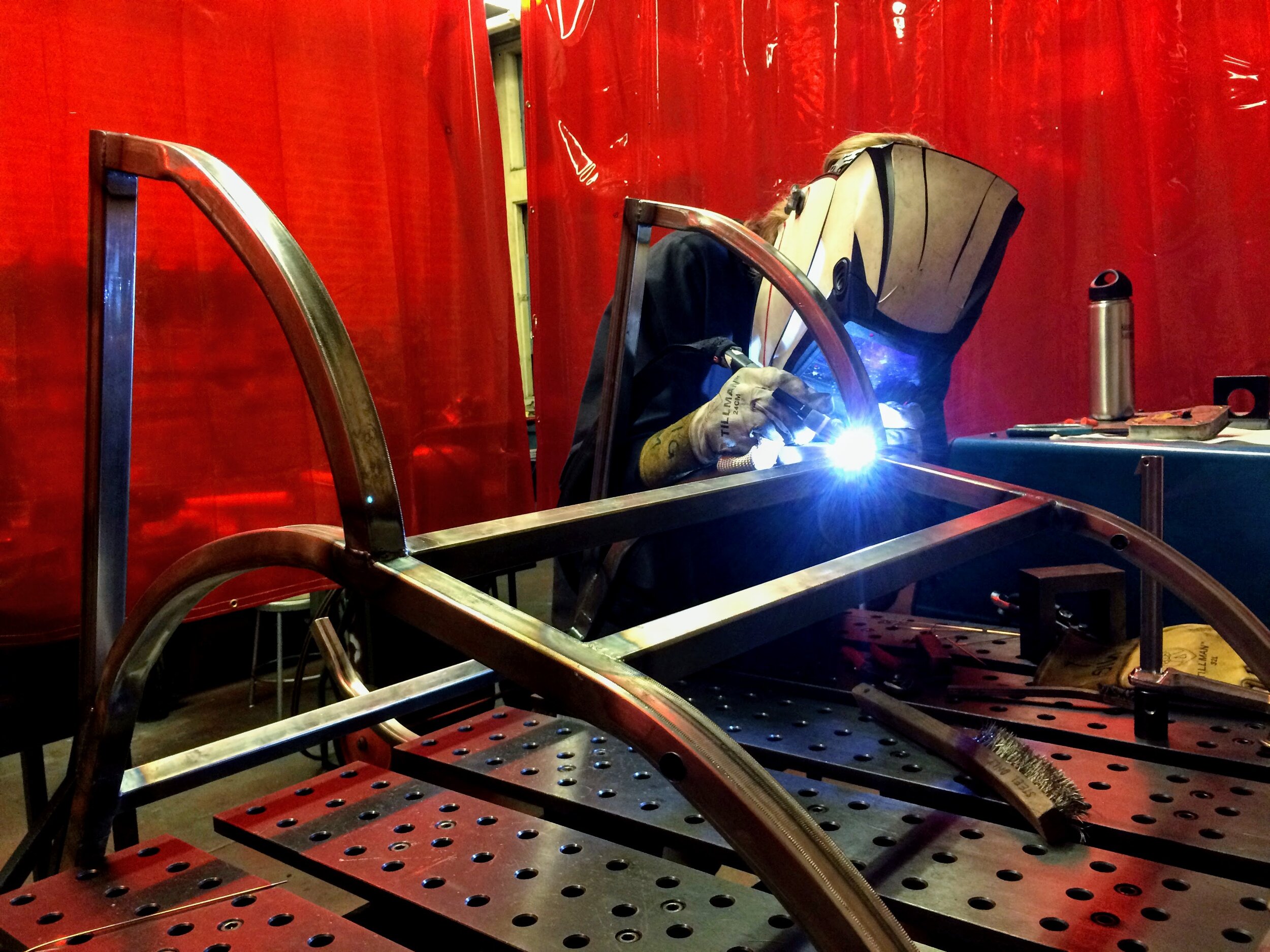

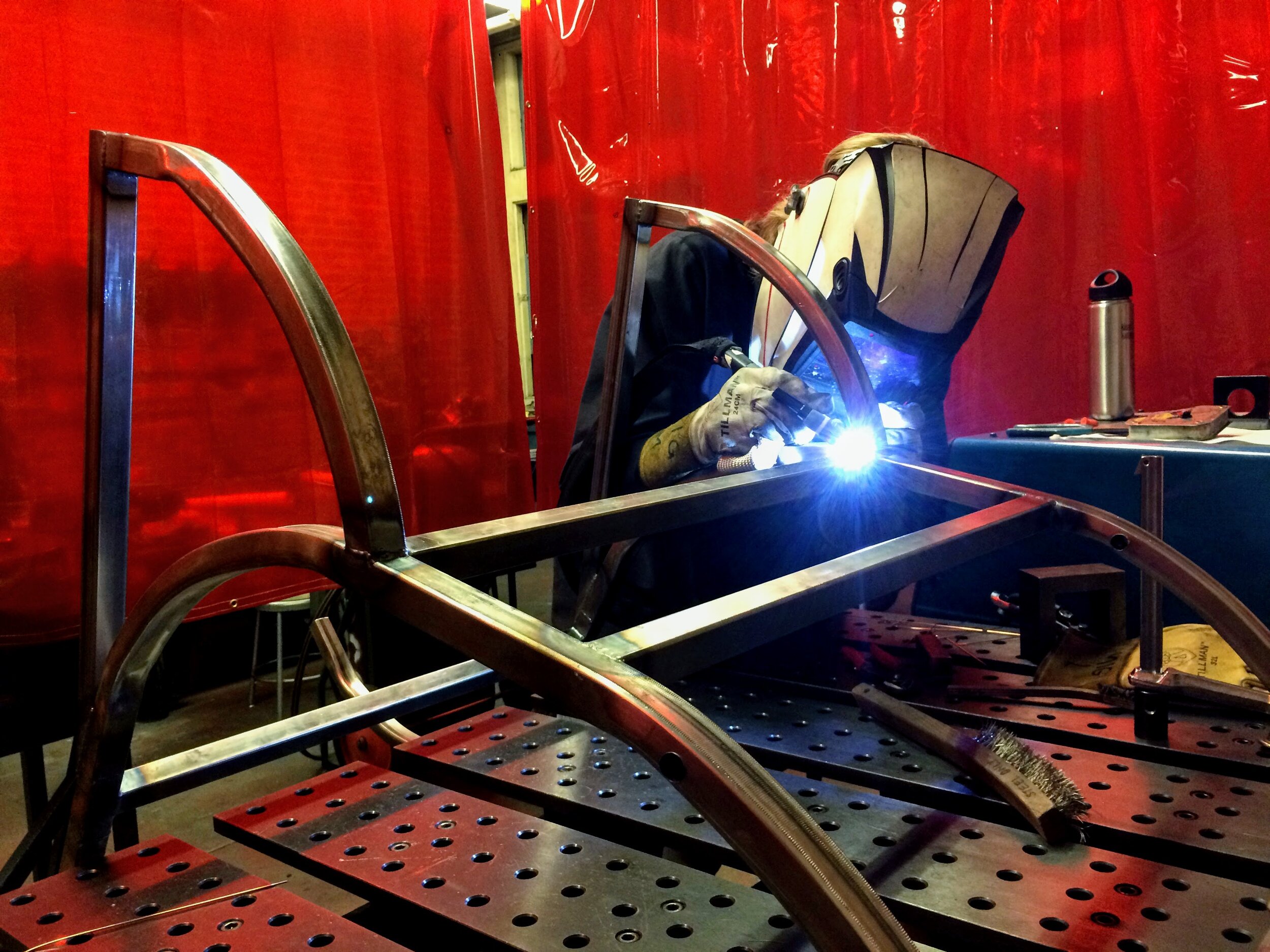

| TIG Welding

| Tube forming

| Sheet metal forming

| Woodworking

Timeline.

| 6 weeks

Context.

This project was my first experience in a machine shop. Before starting, I had never heard of a milling machine or TIG welding. In the process of making Dogwood Wagon, I became empowered and I fell in love with making physical, functional things. I also got pretty good at welding.

Design.

As any gardener knows, not all gardening tools are created equal. I designed this wheelbarrow for my father, a master home gardener. He has been gardening for more than three decades, and he prefers an ergonomic, two-wheeled wheelbarrow. The location of the axle makes it easy to transport and deposit heavy (300 lbs) loads, and the aesthetic matches my father’s meticulously crafted landscape.

Manufacturing lessons.

TIG welding takes practice, lots and lots of practice. It also takes confidence and a willingness to dive into the bead. My best welding happened when I did not hesitate. Bending two long pieces of tubing into the same shape by hand is hard. It helps to have a 1:1 scale drawing and to bend the pieces in parallel, one after another, with the same settings on the bending tool.

I selected fasteners and materials with an eye for beauty and function. Brass acorn nuts pop against dull steel. Marine plywood won’t rot. Bolt heads are counter-bored unobtrusively on the inside. Wood elements give life and personality to this tool.

Initial idea and personal meaning for Dogwood Wagon.

Early explorations of aesthetic.

Functional prototype, testing the two-wheeled design.

Reflecting on the prototype successes and failures.

Sketching to think about fasteners and connections.

Simple manufacturing operations sequence to help myself approach unfamiliar processes.

Using a power ring roller to bend square steel tubing.

Tack weld from a practice welding session.

Practice welds showing the variability of my early welds.

Laying out tubing on a large, 1:1 engineering drawing.

I spent a lot of time welding with the frame in unusual positions.

Quality of the welds improved significantly from my early attempts.

Testing the axle, bearings, and shaft collar connections on the unfinished frame.

Cold setting the frame to the proper geometry.

Getting ready to attach the back legs.

Final welds at a crucial joint.

My welding comfort and skill improved tremendously over the course of this project.

The finished frame sitting on the welding table.